Horizontal vs Vertical Laminar Flow Hoods

Laminar flow hoods are designed to protect samples and parts from particulate contamination. Air flows in a uniform direction with a constant speed within the enclosed bench with little to no crossover air streams. Airborne contamination is filtered through HEPA (filter 99.99% @ 0.3µm) or ULPA (99.999% @0.12µm) filters providing the cleanest work area.

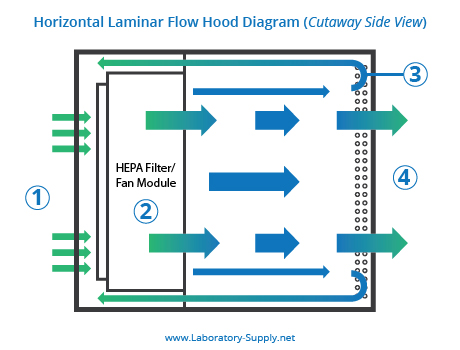

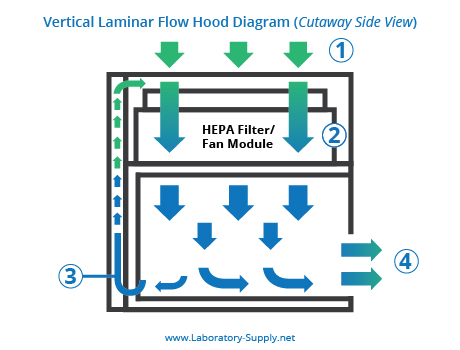

Laminar flow hoods are available in horizontal or vertical airflow configurations. A horizontal flow hood will move air from the back of the unit through HEPA or ULPA filters and to the front of the work surface. A vertical flow hood will move air from the top of the unit through filters and down to the work surface.

Things to consider before purchasing a flow hood is the direction the air should flow, operator safety, clearance requirements, work surface required.

Fans and filters are positioned at the top of a vertical configuration hood. Particles not captured by the filters are pushed out through front access area of the unit. A vertical flow helps move micro-contaminates onto the work surface or the laboratory floor, eliminating contaminants from floating around inside the enclosure. Laboratories with limited floor space may want to go with a vertical configuration. Since the fan and filters sit at the top of the unit the flow hood can be installed on a standard lab bench. Unlike a vertical flow hood, a horizontal flow configuration hood will require additional rear clearance to allow air to enter the enclosure. A deeper workbench and floor space will be required due to fan and filter placement.

Portable vertical laminar flow hoods are also available when space is limited.

When working with smaller particle applications such as the pharmaceutical industry a vertical flow hood may be desired. A sash protector is included with all vertical configuration to protect the operator from inhaling contaminants.

A horizontal flow hood will allow a larger overhead clearance and a deeper workspace. An operators hands and gloves will be less contaminated since air is being pushed from the top of the unit.

Vertical Laminar Flow Hoods

Pro

- Require less floor space

- Can be installed on a standard workbench

- A top filter allows for easy access

- Less cross-contamination of items placed on the work surface

Cons

- Worksurface depth is limited

- May require a step ladder when replacing filters

- Items may not be stacked, obstructs airflow

Pro

- Require less floor space

- Can be installed on a standard workbench

- A top filter allows for easy access

- Less cross-contamination of items placed on the work surface

Cons

- Worksurface depth is limited

- May require a step ladder when replacing filters

- Items may not be stacked, obstructs airflow

Horizontal Laminar Flow Hoods

Pro

- Require less floor space

- Less work surface turbulence

- Larger worksurface depth

Cons

- Worksurface depth is limited

- Large equipment may cause greater turbulence

- Contaminates can be blown into the operator’s face

Pro

- Require less floor space

- Less work surface turbulence

- Larger worksurface depth

Cons

- Worksurface depth is limited

- Large equipment may cause greater turbulence

- Contaminates can be blown into the operator’s face

Horizontal Laminar Flow Hood Diagram

- Air is pulled from the back of the unit

- A fan module pushes the air through HEPA or ULPA filter and into the enclosure

- Air slots along the side edges minimze turbulence in the work area

- Filtered air exits the enclosure back into the room

Vertical Laminar Flow Hood Diagram

- Air is pulled from the top of the unit

- A fan module pushes the air through HEPA or ULPA filter and into the enclosure

- Back plenum allows air to be recirculated, reducing the percentage of dirty air passing through the filter. Extends the life of the filter

- Filtered air exits the enclosure back into the room