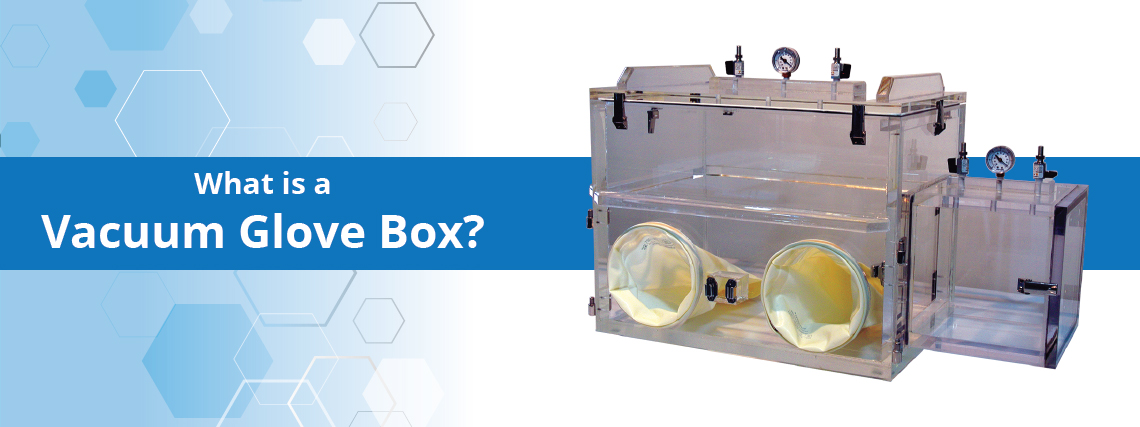

What is a Vacuum Glove Box?

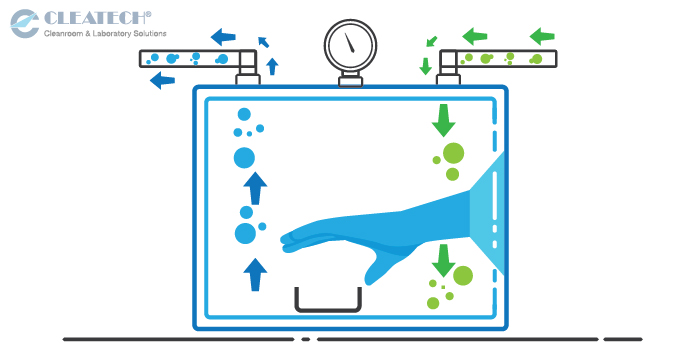

A vacuum glove box combines the best of a vacuum chamber and a glove box. A water-tight enclosure with two glove ports allows for the manipulation of objects within the main chamber. With the help of a vacuum pump, gases are removed from the main chamber and replaced with nitrogen or argon gas creating an inert atmosphere.

This unique piece of laboratory equipment allows researchers to perform experiments in low-pressure, non-combustible environments that require the user to manipulate objects or non-harmful substances.

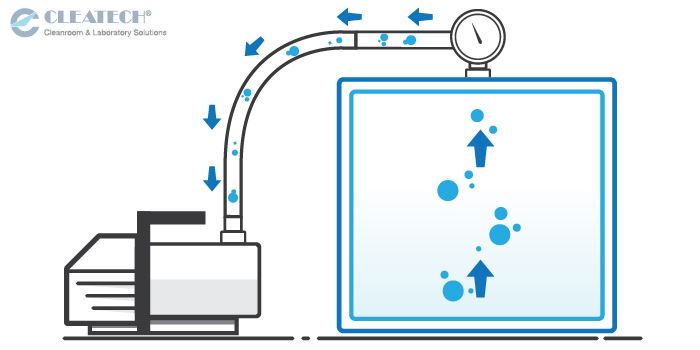

How does a vacuum chamber work?

A vacuum chamber works with the help of a vacuum pump. Air is extracted from inside the chamber to produce a low-pressure environment. Now, in order to reach inert atmosphere nitrogen or argon gas is pumped into the chamber replacing any leftover oxygen. This creates a stable environment for researchers to conduct experiments without the risk of contamination from reactive gases.

Where are vacuum glove boxes used?

Vacuum glove boxes are commonly used in the manufacturing of semiconductor components, lithium battery development, spacecraft engineering, and creating a simulated vacuum environment.

Vacuum chambers can be constructed from any material, but metal is commonly used. Other materials that can be used to construct a vacuum chamber are glass, high-density ceramic, and acrylic. Strong and affordable material is acrylic, here is a list of benefits.

Benefits of Acrylic Material

Clear acrylic sheets can be used to construct a vacuum glove box. Here are a few benefits why acrylic is a great material to build a vacuum chamber.

Light-weight

Acrylic is 50% lighter and much stronger than glass. This is perfect where weight is an issue.

Cost-effective

An acrylic enclosure is typically half the price of a steel or glass vacuum chamber. This material is not only lighter and stronger but affordable.

Impact resistant

4-5 time more impact resistant than glass make acrylic an ideal material to build a robust vacuum chamber.

Transparent

Unlike many of the metals used to construct a vacuum chamber, acrylic is clear allowing users to observe inside the chamber.

Easy to Maintain

A microfiber cloth and water is enough to clean slight blemishes and dirt. Avoid ammonia-based products will extend the life of the material.